Have you ever considered the extent to which PCB assembly manufacturers like OurPCB are truly reshaping the electronics industry? With advancements in production processes, quality control measures, and the incorporation of cutting-edge technologies, OurPCB is paving the way for a new era in electronics manufacturing.

The impact on consumer electronics is profound, but there’s more to uncover about how these changes are influencing the devices we use daily. Learn more about how this leading pcb assembly manufacturer service is driving innovation.

Key Takeaways

- Enhanced production processes with automation and lean principles boost efficiency.

- Advanced quality control measures like AOI ensure high product standards.

- Efficiency improvements through automation and integration of cutting-edge technologies.

- Impact on consumer electronics: improved performance, durability, and energy efficiency.

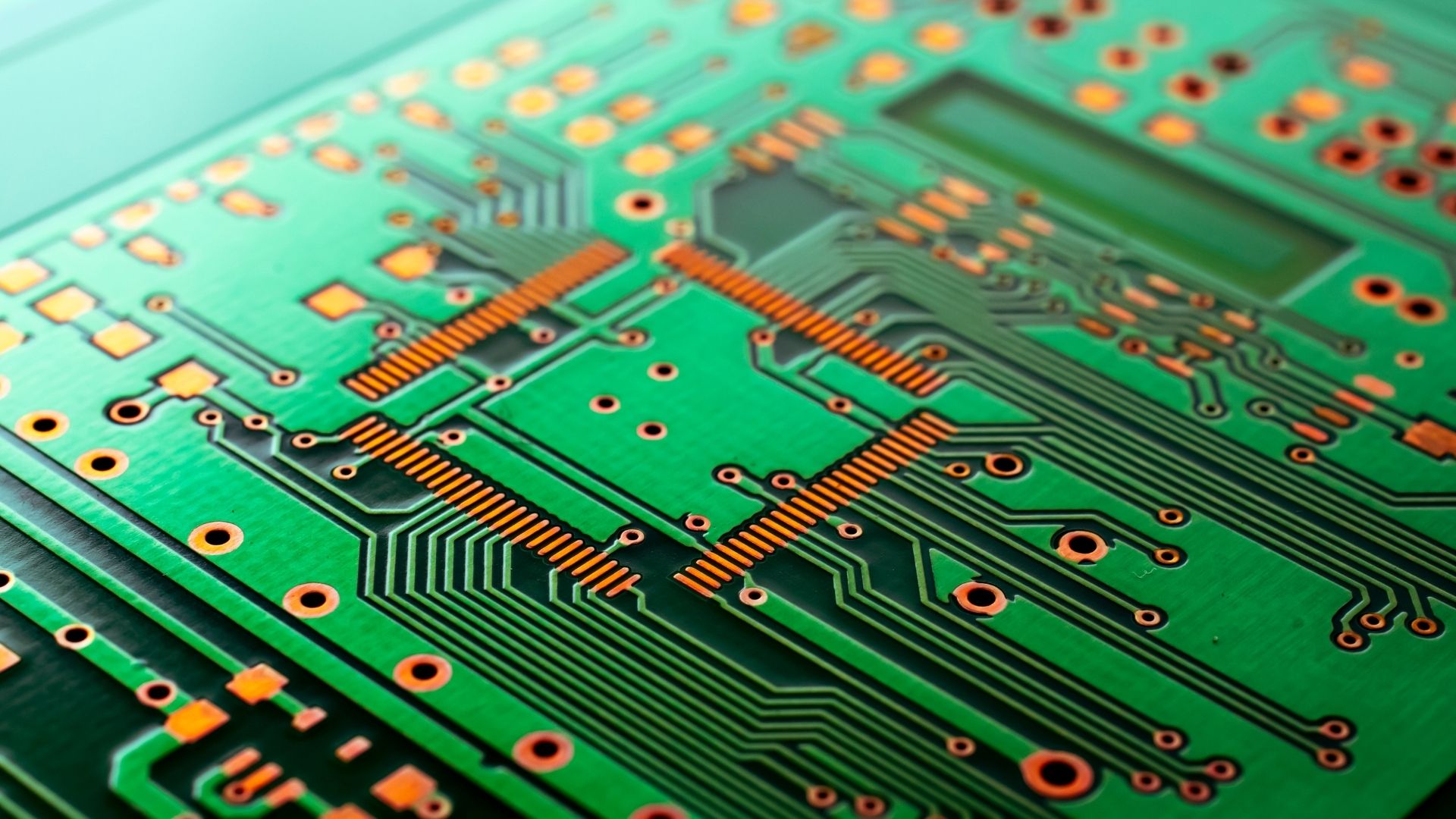

Enhanced Production Processes

Enhancing production processes in PCB assembly manufacturing yields increased efficiency and quality. By implementing streamlined workflows and optimizing manufacturing techniques, you can significantly boost productivity while maintaining high standards.

One key aspect of enhancing production processes is the adoption of automated assembly equipment. These machines can perform tasks with precision and speed, reducing the margin of error and increasing the overall output capacity of your facility.

Another important factor to consider is the implementation of lean manufacturing principles. By eliminating waste and unnecessary steps in the production process, you can achieve a more efficient workflow that maximizes resources and minimizes costs. This approach not only improves the bottom line but also enhances the overall quality of the final product.

Moreover, investing in employee training and development can also enhance production processes. By ensuring that your staff is well-versed in the latest technologies and best practices, you can further optimize your manufacturing operations. Overall, focusing on enhancing production processes is crucial for staying competitive in the ever-evolving electronics industry.

Advanced Quality Control Measures

To ensure top-notch quality in PCB assembly manufacturing, implementing advanced quality control measures is essential. Here are some key measures that PCB assembly manufacturers are using to enhance the quality of their products:

- Automated Optical Inspection (AOI): AOI systems use cameras and algorithms to detect defects such as missing components, misaligned parts, or soldering issues, ensuring high product quality.

- X-Ray Inspection: X-ray machines are employed to inspect hidden solder joints, verify wire bonding, and check for any defects that aren’t visible to the naked eye, guaranteeing the integrity of the assembly.

- Functional Testing: Manufacturers conduct thorough functional tests to ensure that the assembled PCBs meet all performance specifications and function as intended before they’re shipped out.

- Traceability Systems: Implementing traceability systems allows for tracking each component used in the assembly process, aiding in identifying and rectifying any issues that may arise, thus ensuring consistent quality standards.

Efficiency Improvements and Automation

Efficiency in PCB assembly manufacturing is being significantly boosted through the integration of automation technologies, revolutionizing the production processes. By implementing automated systems for tasks such as component placement, soldering, and quality control, manufacturers are streamlining operations and enhancing overall productivity. Automated machinery can work around the clock without fatigue, leading to faster turnaround times and increased output levels.

Automation also plays a crucial role in error reduction by minimizing the chances of human mistakes during the assembly process. With precision-driven automated equipment, the consistency and accuracy of PCB assembly are greatly improved, resulting in higher quality end products. Additionally, automation enables real-time monitoring and data collection, allowing for quick adjustments and optimizations to be made on the production line.

Implementation of Cutting-Edge Technologies

The utilization of cutting-edge technologies in PCB assembly manufacturing is propelling the industry towards unprecedented advancements and capabilities. This infusion of state-of-the-art tools and techniques is revolutionizing the way electronic components are assembled and integrated.

Here are some key ways in which these technologies are transforming the PCB assembly process:

- Advanced Robotics: Robotic arms equipped with AI algorithms are streamlining the assembly line, enhancing precision, and increasing production speeds.

- Machine Learning Algorithms: These algorithms are optimizing quality control processes, identifying defects with greater accuracy, and ensuring higher product reliability.

- 3D Printing: Additive manufacturing techniques are being utilized to create intricate PCB designs quickly and cost-effectively.

- IoT Integration: Implementing Internet of Things (IoT) technology in PCB assembly allows for real-time monitoring of equipment performance, predictive maintenance, and overall process optimization.

Impact on Consumer Electronics

Revolutionizing the landscape of consumer electronics, PCB assembly manufacturers are incorporating cutting-edge technologies to enhance product performance and functionality. By leveraging advanced PCB assembly techniques, consumer electronic devices such as smartphones, laptops, and smart home gadgets are becoming more powerful, efficient, and compact. These innovations not only improve the overall user experience but also enable manufacturers to introduce new features and functionalities at a rapid pace.

One significant impact of PCB assembly advancements in consumer electronics is the increased integration of components. Manufacturers can now pack more functionality into smaller devices, making them sleeker and more portable without compromising performance. Additionally, the use of high-density interconnects and advanced materials has led to improved durability and reliability in consumer electronics products.

Moreover, the adoption of innovative PCB assembly processes has contributed to the development of energy-efficient devices, reducing power consumption and extending battery life in portable electronics. As a consumer, you can expect future electronic products to be more powerful, energy-efficient, and feature-rich, thanks to the continuous evolution of PCB assembly technologies.

Can PCB Assembly Manufacturers Customize Their Production Processes According to Specific Customer Requirements?

Yes, PCB assembly manufacturers can customize their production processes according to specific customer requirements. By understanding and adapting to your needs, they ensure that the final product meets your exact specifications and quality standards.

How Do PCB Assembly Manufacturers Ensure the Security and Confidentiality of Their Clients’ Designs and Intellectual Property?

To ensure the security of your designs and intellectual property, PCB assembly manufacturers implement strict access controls, encryption protocols, and confidentiality agreements. Your information is safeguarded through robust cybersecurity measures and a commitment to protecting your valuable assets.

What Measures Are in Place to Address Potential Environmental Impacts of PCB Manufacturing Processes?

To address potential environmental impacts of PCB manufacturing processes, you implement eco-friendly practices, recycle waste materials, and adhere to strict regulations. Your commitment to sustainability ensures that your operations have minimal negative effects on the environment.

Are There Any Ongoing Research and Development Initiatives Within PCB Assembly Manufacturing That Are Shaping the Future of the Industry?

In the world of PCB assembly manufacturing, ongoing research and development initiatives continue to shape the future of the industry. Innovations in technology, materials, and processes lead the way towards exciting advancements.

How Do PCB Assembly Manufacturers Stay Ahead of Market Trends and Adapt to Changing Consumer Preferences in the Electronics Industry?

To stay ahead of market trends and adapt to changing consumer preferences in the electronics industry, you must conduct regular market research, invest in innovative technologies, and prioritize flexibility in your production processes.